POLYe FARM

A DOMESTIC MYCOREMEDIATION POD

WESLEYAN UNIVERSITY SENIOR THESIS IN STUDIO ART

2020

ABOUT

For my senior thesis, I explored the combination of biology, engineering and product design to create a domestic product that served as not only a response to global issues of plastic pollution, but also as an educational tool for the everyday urban user. My senior year was dedicated to researching several strains of fungus that could degrade soft plastic waste into a compostable material, and then designing a prototype of a small-scale mushroom farm and plastic composter around that. Due to a recycling and import policy change in several Asiatic countries within the last 2 years, plastic waste recycling in the U.S. has practically come to a stand still, and has revealed our own failures in coping with our own plastic waste. Soft polyethylene plastics, such as shopping bags, food wrappers, and cling film compose approximately 90% of single use plastic waste that is unable to be processed by large industrial facilities, resulting in these plastics accumulating in landfills and the environment. These plastics are most commonly found in the house, so POLYe FARM serves as a way to remediate individual plastic waste while creating a self-sustaining ecosystem, exploring how we can use biology to address global issues. Unfortunately my research and design was cut short due to the Covid-19 lockdowns that closed my school, but I would love to see this project through one day.

Myco-remediation is the budding practice of using fungus to break down human-made pollutants, and presents a great opportunity for designers. Though this research is incredibly new and will potentially need years to fully develop, I was inspired to create a domestic product that could house this biological process. My senior year, I grew a strain of mushroom called Pleurotus Ostreatus (Oyster Mushroom) that have been shown to degrade polyethylene. While my testing was cut short, the mycelium grew rapidly and the mushroom began pinning. New research into fungal degradation of plastic shows that many species - including the edible Oyster Mushroom - are able to break down the polycarbonate chains of these plastics into their mycelium (the white root system the mushrooms) resulting in a non-toxic substance that can be subsequently composted. Because of the edible nature of the Oyster mushroom, as well as the fact that these soft plastics are mostly found in the home, I chose to make the product on a domestic scale - perhaps something you could find on a kitchen counter.

RESEARCH

I was influenced by the tradition of “DIY” within the mushroom farming community, specifically the 10 gallon bucket with drilled holes set up that many amateur mushroom growers often use.

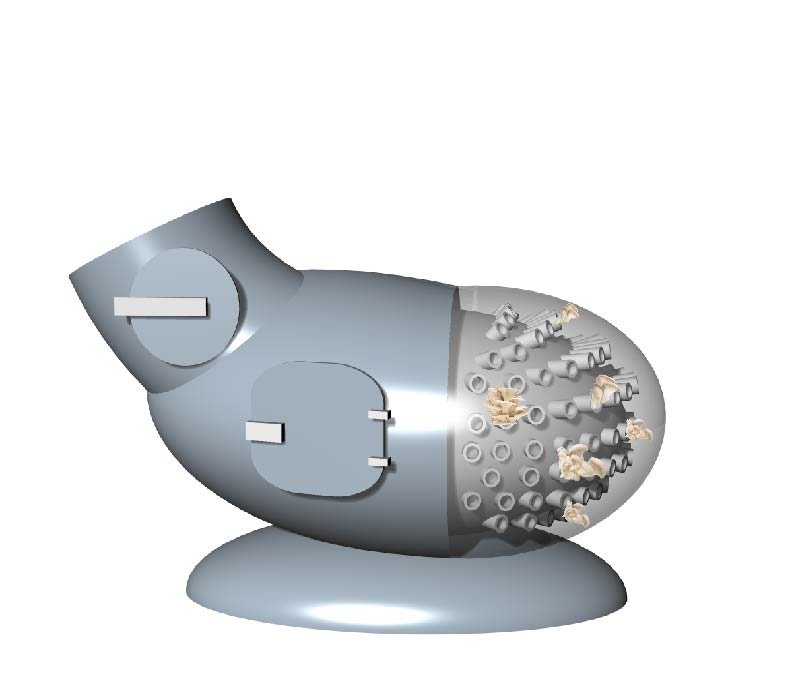

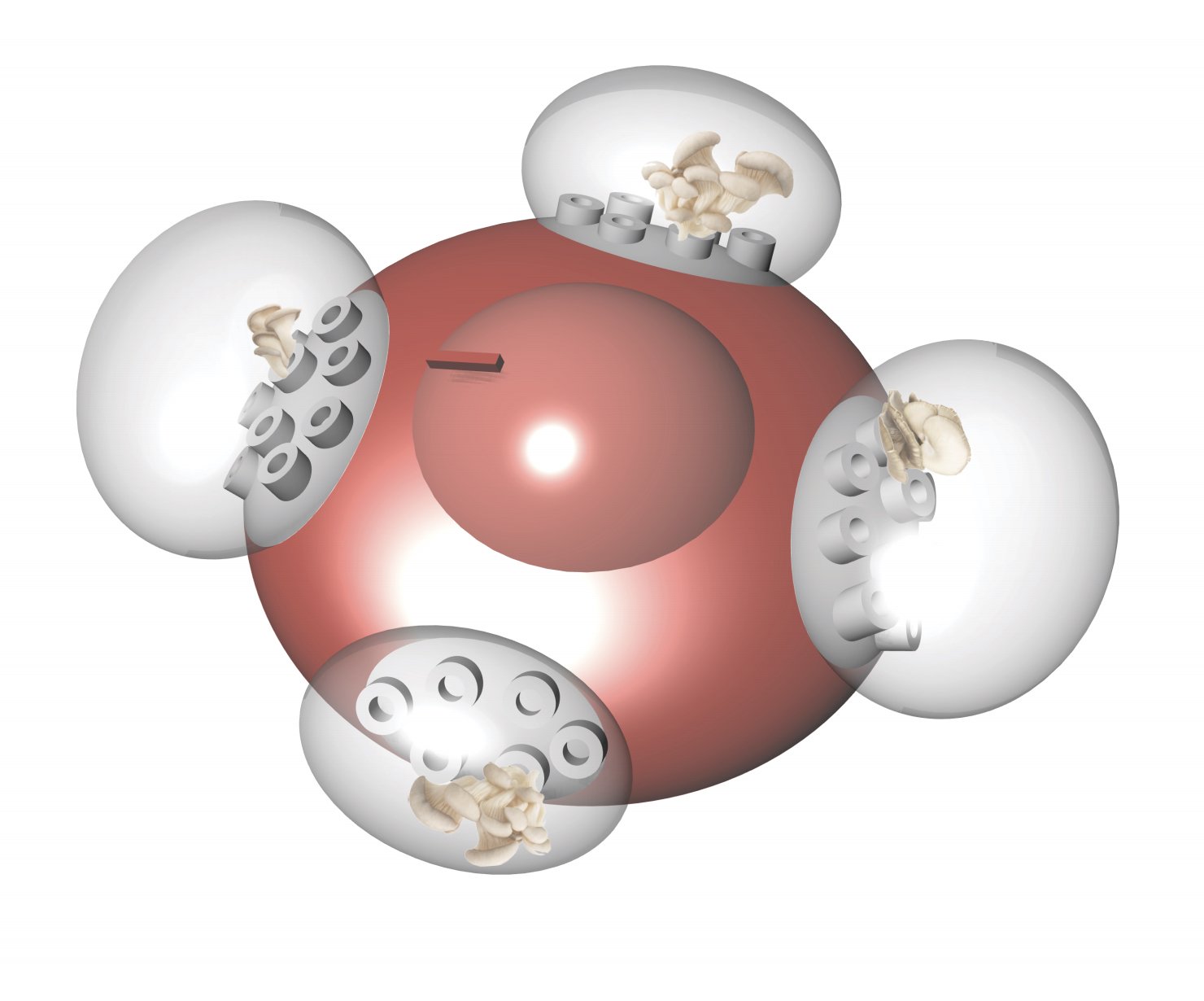

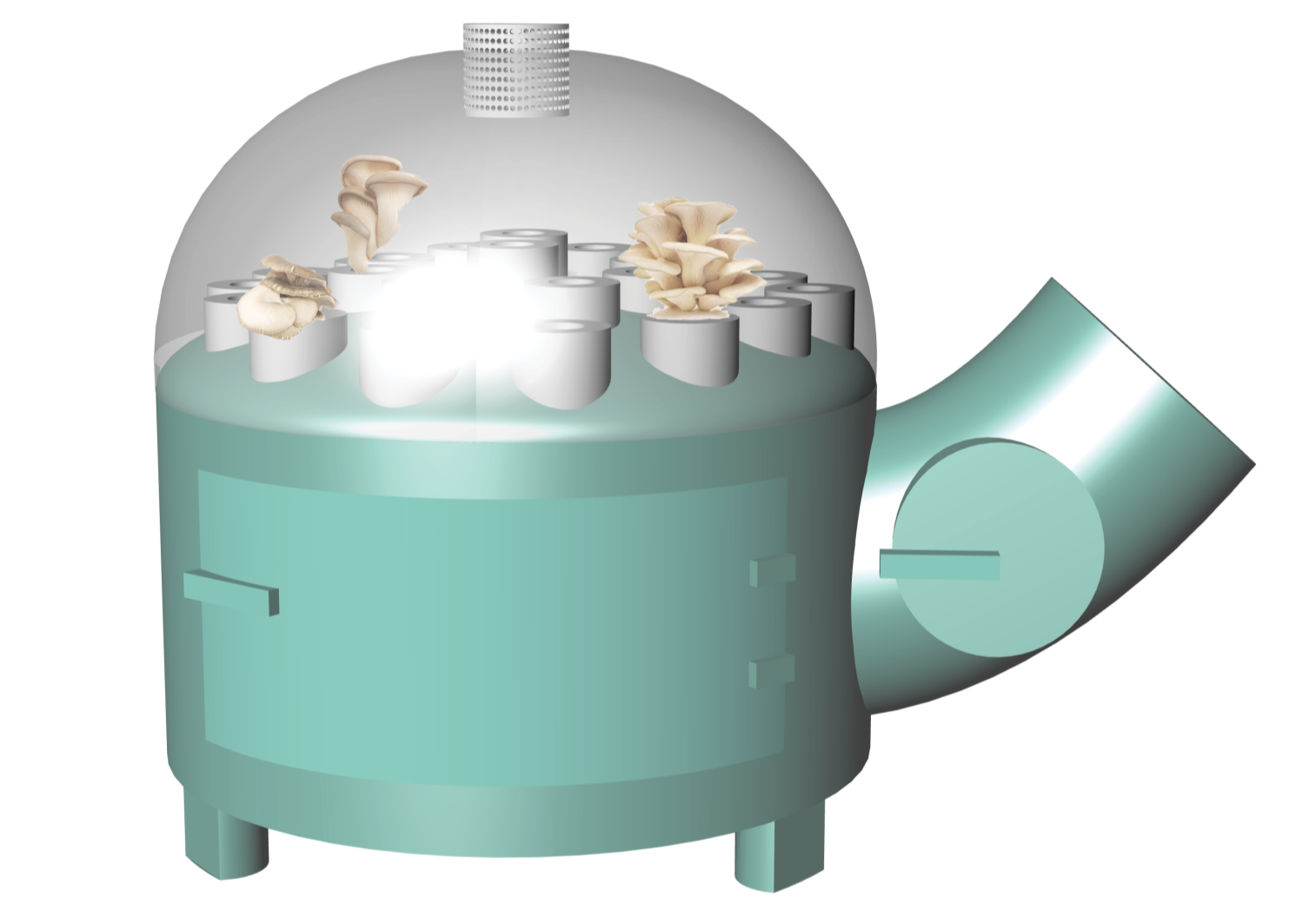

Preliminary models to figure out shape

Iteration one

Iteration two

Iteration three

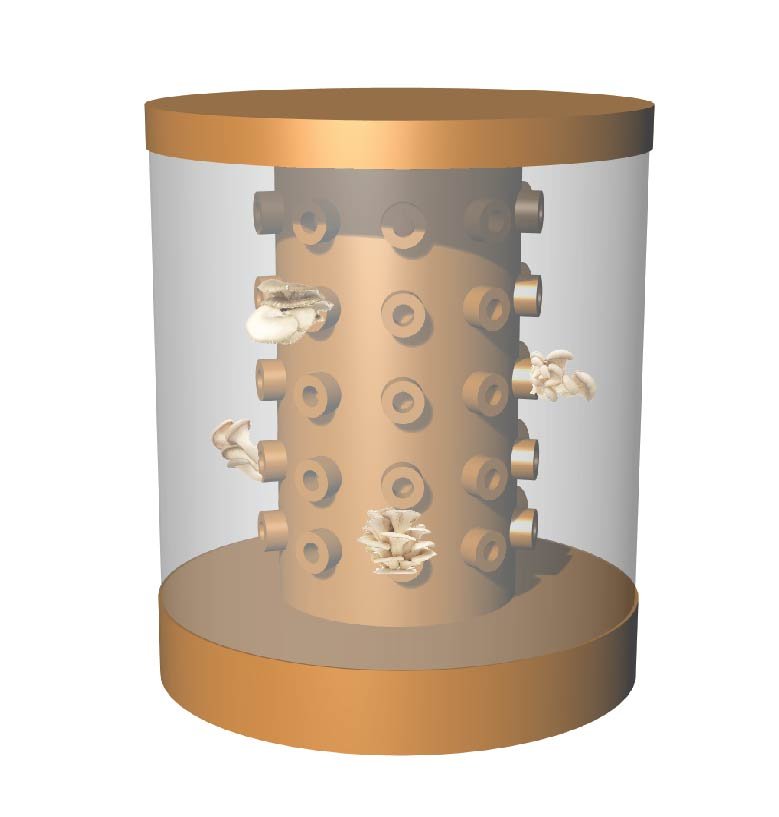

Iteration four. This early design was eventually chosen for the final product due to it being the most accessible, and the best at creating the ideal conditions for mushrooms to grow.

Early concept design.

Early section drawing

Early 3D Printed prototype of the inner chamber.

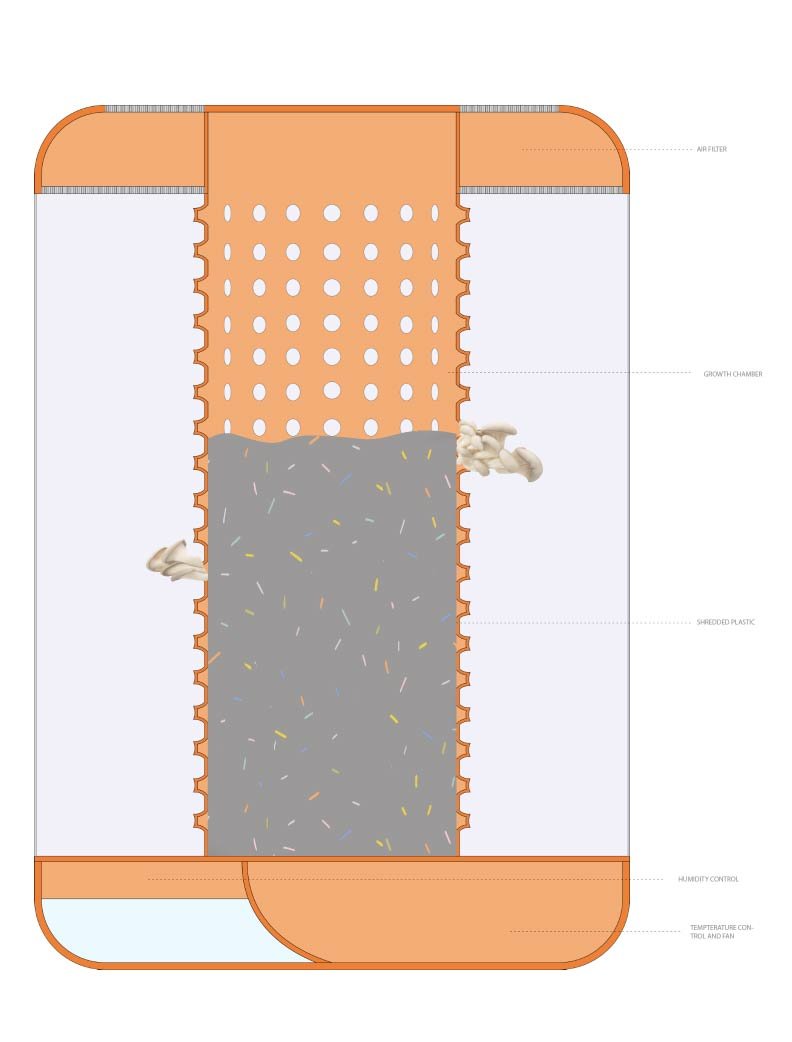

POLYe section drawings. Assembled and Exploded

Details of each of POLYe’s simple components. Above - the top section includes a small funnel for water, two caps, and a pocket for an air filter sponge - allowing for air exchange but preventing dust and pests from entering the main chamber.

Top right - the base includes a water basin connecting to a tube which can be filled from the top and helps keep the interior humid.

Finally - the bottom right illustrates the central chamber. This is where the plastic substrate and the mushroom spores will fit. As the mycelium grows, it breaks apart the plastic and the mushroom fruits out from the small holes that similarly radiate throughout the main chamber.

Material Breakdown and exploded diagram of PolyE Farm

POLYe FARM packaging would have been made from recycled cardboard and includes instructions for use, as well as a small description of the kit.

Because of the untimely closure of my university just was a few months out from my thesis show, we were tasked with trying to represent what the show would have looked like in the campus’s gallery. My final showing would have been composed of two finished POLYe FARM kits - one assembled and in use (perhaps already sprouting mushrooms) - and one disassembled as to show the viewers each component of the design. Additionally, I would have had about 5 large posters hanging which would serve as a product breakdown, and informational tool.